PET Bottle / Flakes Washing Line

Soft Plastic and Flakes Compacting & Granulation System

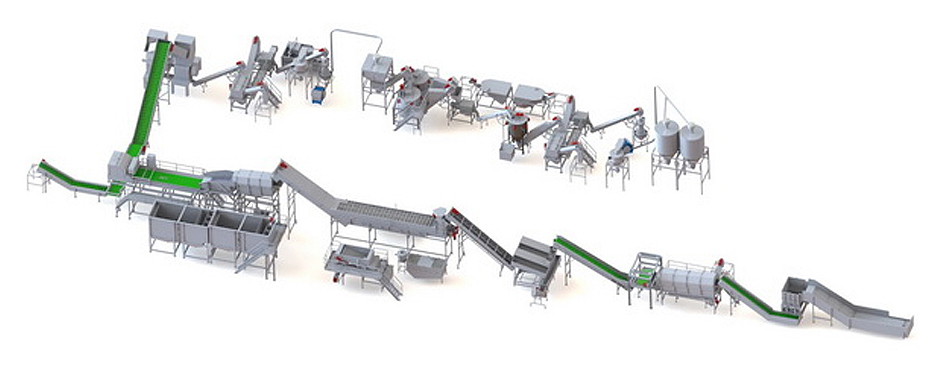

PET Bottle / Flakes Washing Line is one of the main recycling series of KiTech machinery. This system applies to waste PET plastics recycling with different pollution levels. Which canremove ferrous and nonferrous metals, sand, oil, glue, rubber, wood, PE/ PP/ BOPP labels and many other different contaminants efficiently. It also provides a good solution for mixedcolor PET and materials containing PVC.The modular design makes it easy to have diferent combinations according to the requirements of the customers, such as bottle to fiber, bottleto flake, bottle to bottle washing system. KiTech provides 500-6000 kg/h economy and high-level automatical production lines with different configurations.

Metal Sorting |

Label Remover |

Pre-washer |

Crusher |

Hot Washer |

Friction Washer |

Floating Washer |

Centrifugal Dryer |

Zig-zag Separator |

Water Treatment System |

Color Sorter |

Material Sorter |

| 1.Bale Breaker | 2.Belt Converyor | 3.Trommel | 4.Belt Convey |

| 5.Vibration Feeder | 6.Magnetic Drum | 7.Eddy Current Separator | 8.Belt Conveyor |

| 9.Label Remover | 10.Belt Conveyor | 11.Re-washer | 12.Screw Loader |

| 13.Vbration Feeder | 14.Bottle Optical Sorter | 15.Manual Sorting Section | 16.Belt Conveyor |

| 17.Crusherx2 | 18.Screw Loader | 19.Floating Tank | 20.Friction Washer |

| 21.High-speed Hot Washer | 22.Low-speed Hot Washer | 23.Centrifugal Dryer | 24.Screw Loader |

| 25.Floating Tank | 26.Floating Tank | 27.Floating Tank | 28.Centrifugal Dryer |

| 29.Zig-zag Separator | 30.Flakes Optical Sorter | 31.Silo |

Ability |

Stability |

Thanks to innovative PET washing te chnology and high quality performance. KiTech intelligent recycling and washing system removes the most difficult contaminants from waste plastics, and provides high quality and purit washing results for customers | Kitech PET washing system is available for 24 hours working non-stop operation. |

Efficiency |

Modularity |

Kitech PET washing system is designed in all details for efficiency improving. The modular design could simplify the planning and accelerate the implementation. The system have very low consumption values for electricity, water and labor. The operating costs and | Kitech PET washing system is a flexible modular system All elements required by any customer for different application could be combined freely, This design reduces |

Control |

Service |

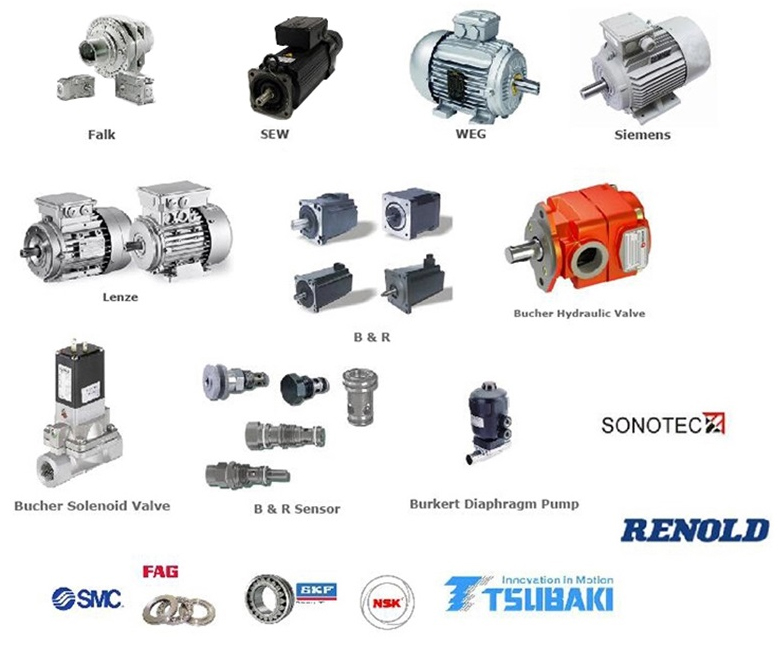

Automatic modular control of KiTech PET washing system reduces the labor operation,makes the whole system easier and more reliable to control, the remotes monitoring and maintenance are available for different production lines. The intelligent control has display for operating data, it also collects the data of the consumption and the capacity from production line. Which ensures the connection between the enterprises and the Internet,will improve the efficiency of enterprise management | KiTech PET washing system is a flexible and customer- oriented recycling solution. All the components of the /hole line is globally well-known brands, which ensures the reliable |

Electrical Parts

Technical Data

Sheet Grade PET Washing System

TYPE | Capacity (kg/h) | Energy Consumption (kw/h) | Steam Consumption (kg/h) | Chemical Consumption (kg/h) | Water Consumption (ton/h) | Installation Power (kw) | Space(m²) | Man Power (persons/shift) |

| PET500 | 500 | 110 | 500 | 10 | 0.7 | 220 | 700 | 6 |

| PET1000 | 1000 | 170 | 600 | 14 | 1.5 | 395 | 800 | 8 |

| PET2000 | 2000 | 340 | 1000 | 18 | 3 | 430 | 1200 | 10 |

| PET3000 | 3000 | 460 | 1200 | 28 | 4.5 | 590 | 1500 | 12 |

| PET5000 | 5000 | 680 | 1500 | 50 | 8 | 850 | 2000 | 12 |

Fiber Grade PET Washing System

TYPE | Capacity (kg/h) | Energy Consumption (kw/h) | Steam Consumption (kg/h) | Chemical Consumption(kg/h) | Water Consumption (ton/h) | nstallation Power (kw) | Space(m²) | Man Power (persons/shift) |

| PET500 | 500 | 70 | 300 | 10 | 0.7 | 190 | 500 | 10 |

| PET1000 | 1000 | 140 | 500 | 12 | 1.5 | 340 | 700 | 12 |

| PET2000 | 2000 | 280 | 800 | 16 | 3 | 390 | 1000 | 16 |

| PET3000 | 3000 | 350 | 1000 | 25 | 4.5 | 520 | 1200 | 18 |

| PET5000 | 5000 | 590 | 1200 | 40 | 8 | 920 | 1500 | 25 |