AGH General Purpose Heavy Duty Granulator

AGH General Purpose Heavy Duty Granulator

AGX/AGS/AGF/AGH

KEY FEATURES >

1. Large diameter rotor 2. Machining pocket turret 3. Surface reinforcement optional 4. Concave square knife 5. Solid shell 6. Heavy bearing 7. Universal coupling 8. High torque gearbox 9. Hydraulic swing gate valve 10. Hydraulic pushing 11. Transmission shaft bolt 12. Multiple rotor design 13. Two speed hydraulic system 14. Oil cooling of gearbox 15. Toothed shift 16. Amp instrument control

OPTIONS >

1. Hydraulic feeding 2. Gearbox with shrink disc 3. Rotor cooling 4. Isolation between tubes 5. Touch screen PLC 6. Funnel type observation mirror 7. Increase motor power 8. Hydraulic operation 9. Color customization 10. Turbine hydraulic 11. Wear resistant shell plate

GENERAL DESCRIPTION

AGH heavy crusher has a central hinged two-piece cutting chamber, which adopts a solid welded steel structure, and the upper and lower parts of the shell intersect horizontally. The reversible stator cutter with double cutting edges is installed in the lower part of the housing as a single element, which allows multiple re sharpening and adjustment of the stator cutter. There is a hinged cradle and hinged door for easy access. The rotor is a heavy-duty paddle type design with a knife cover to protect the blade when machining abrasive applications. In contrast to the rotor, the knife mounting bolt is screwed into the mounting plate. All tools are made of chromium nickel tool steel as standard material, but when machining particularly abrasive applications, a specially designed wear-resistant rotor is provided, using wear-resistant steel parts and cemented carbide surfaces. Compared with other rotor designs, V-CUT geometry has obvious advantages, including higher throughput and lower power consumption, better crushing quality and lower noise level. The specially designed tool position fixture can adjust the tool position from the outside of the machine, greatly reducing the downtime required for changing the tool position. The base adopts solid welding structure and shockproof rubber feet to reduce vibration and noise. The driving motor is installed on the tension guide rail, which is convenient to adjust the tension of V-belt. Aggregate suction tank. The hopper is specially designed with three sets of curtains to prevent materials from hanging upside down. There are emergency stop buttons on the fuselage and control panel. When the front panel is opened, the safety switch can prevent the machine from starting.

APPLICATIONS

AGH heavy crusher has a wide range of applications in various industries, such as: plastic / Wood / paper / fuel

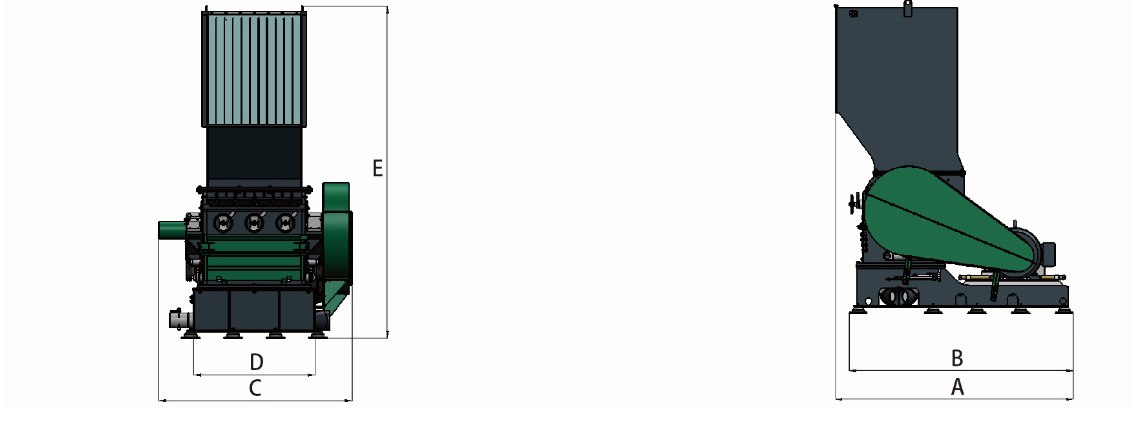

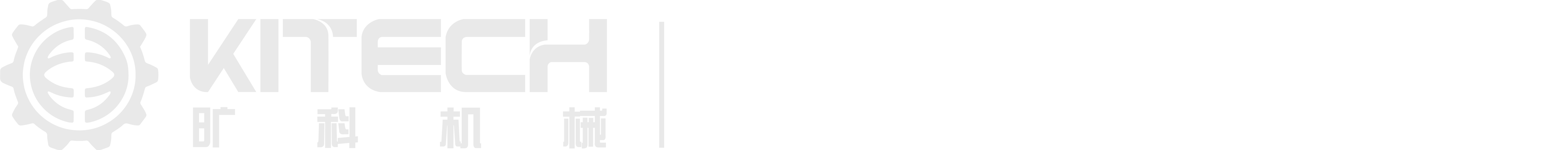

TECHNICAL DATA

| ITEM | UNIT | AGH350/500 | AGH500/600 | AGH600/800 | AGH500/1000 | |

| Rotor Diameter | mm | 350 | 500 | 600 | 500 | |

| Rotor Width | mm | 500 | 600 | 800 | 1000 | |

| Rotor Knives | pcs | 3x2/5x2 | 3x2/5x2 | 3x2/5x2 | 3x2/5x2 | |

| Stator Knives | row | 2/3 | 2/3 | 2/3 | 2/3 | |

| Cutting Chamber Dimensions | mm | 516x460 | 636x590 | 790X695 | 985x590 | |

| Motor Power | kw | 15-22 | 37-55 | 55-90 | 55-90 | |

Dimensions | A | mm | 1800 | 2080 | 2300 | 2230 |

| B | mm | 1600 | 1850 | 2100 | 2000 | |

| C | mm | 1250 | 1530 | 1850 | 1950 | |

| D | mm | 770 | 940 | 1120 | 1350 | |

| E | mm | 2500 | 2620 | 3000 | 2860 | |

| ITEM | UNIT | AGH700/1000 | AGH800/1200 | AGH800/1600 | AGH800/2000 | |

| Rotor Diameter | mm | 700 | 800 | 800 | 800 | |

| Rotor Width | mm | 1000 | 1200 | 1600 | 2000 | |

| Rotor Knives | pcs | 5x2/7x2/9x2 | 7x2/9x2 | 7x4/9x4 | 7x4/9x4 | |

| Stator Knives | row | 2/3 | 2/3 | 2/3 | 2/3 | |

| Cutting Chamber Dimensions | mm | 985x800 | 1150x915 | 1570x915 | 1960x915 | |

| Motor Power | kw | 75-110 | 110-160 | 132-200 | 160-200x2 | |

Dimensions | A | mm | 2800 | 3100 | 3140 | 2740 |

| B | mm | 2500 | 2800 | 2800 | 2600 | |

| C | mm | 2060 | 2360 | 2800 | 3460 | |

| D | mm | 1290 | 1530 | 1960 | 2250 | |

| E | mm | 3420 | 3820 | 4250 | 4775 | |