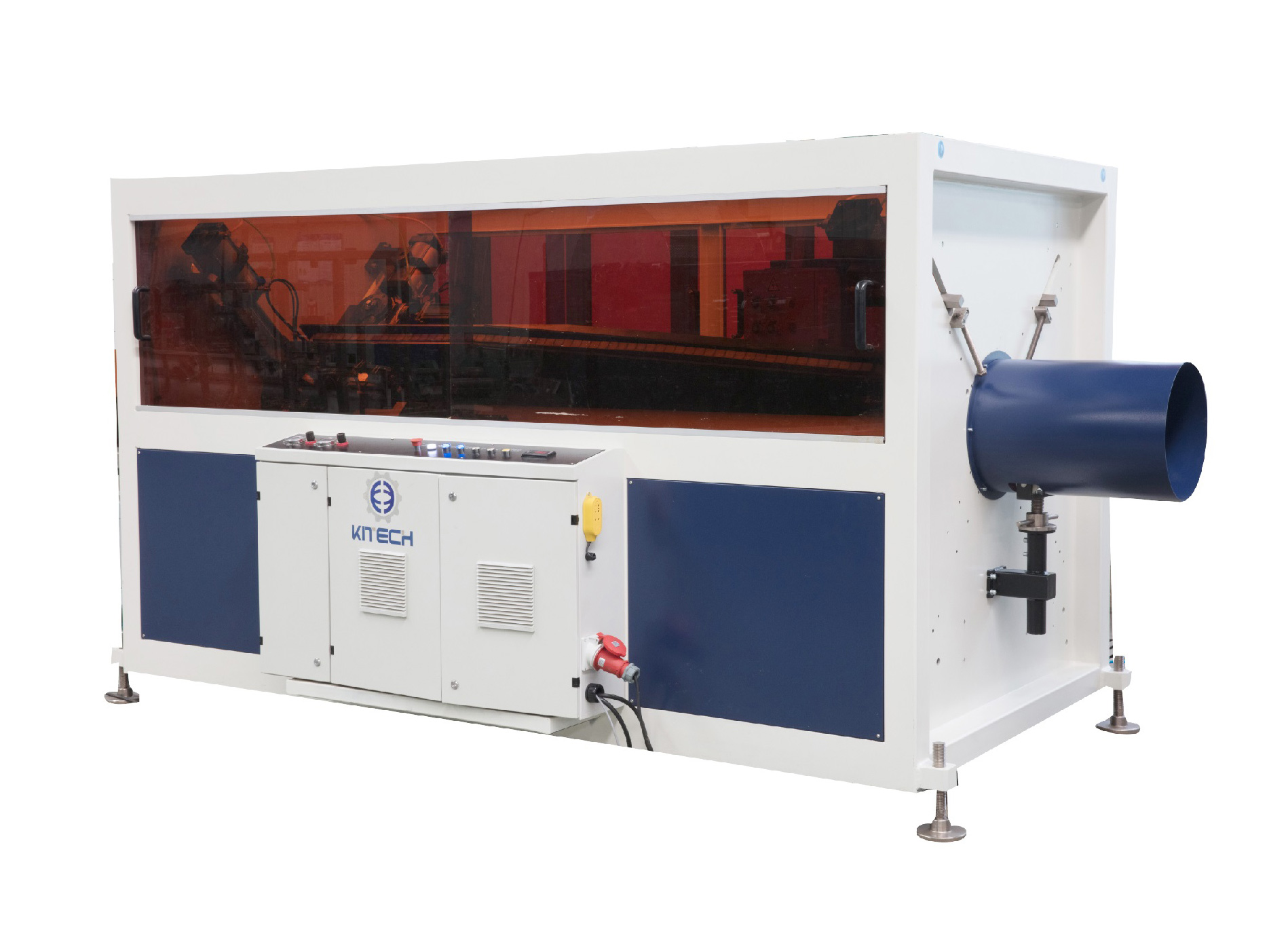

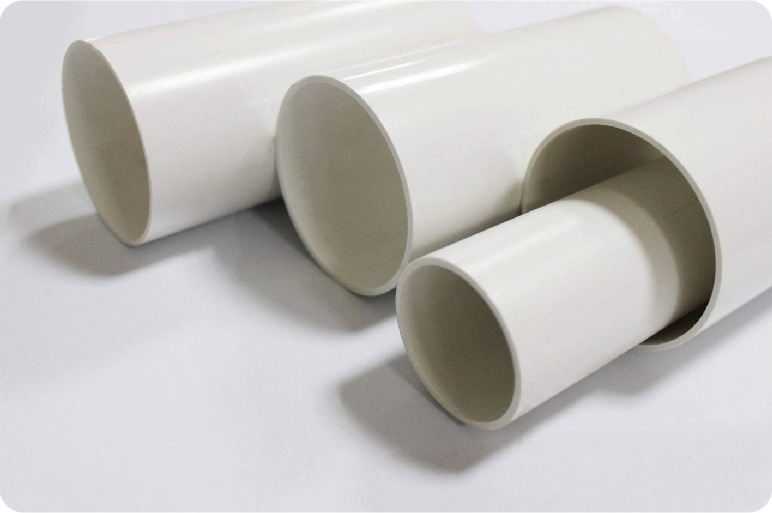

PVC Pipe extrusion equipment

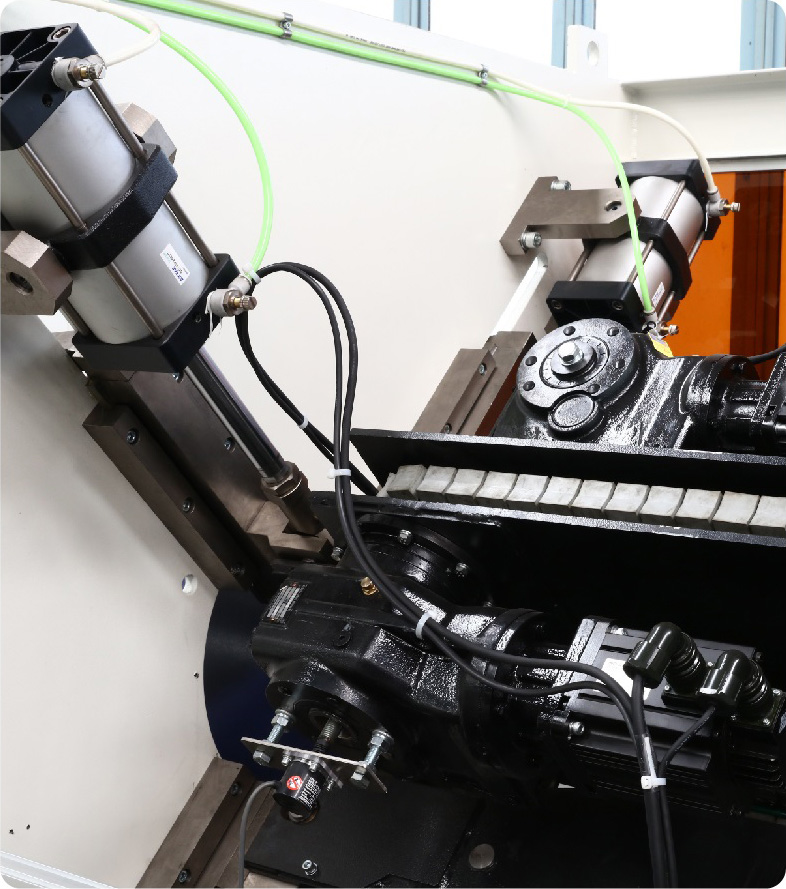

Kitech provides a complete set of PVC, m-pvc, c-pvc pipe extrusion equipment and production process for various water supply and drainage, sewage, threading, fire fighting, drilling and other industries. Kitech adopts SJZ series conical and SJP series parallel twin-screw extruders, single / double chuck die head, 2 / 3 / 4 / 6 / 8 multi-channel traction, planetary sawing machine with chamfering function, U / R and rectangular packer. Our production line can be used to process up to 800mm in diameter and 1-30mm in wall thickness.

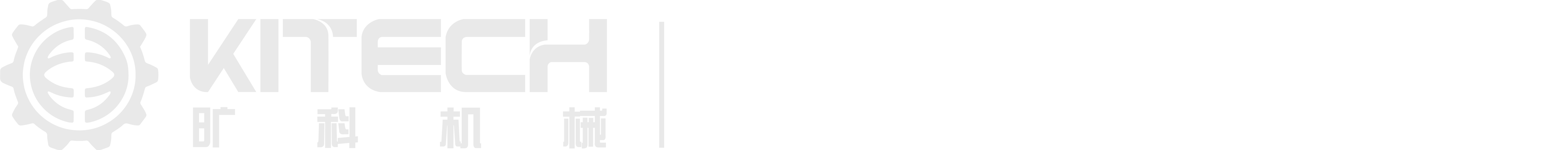

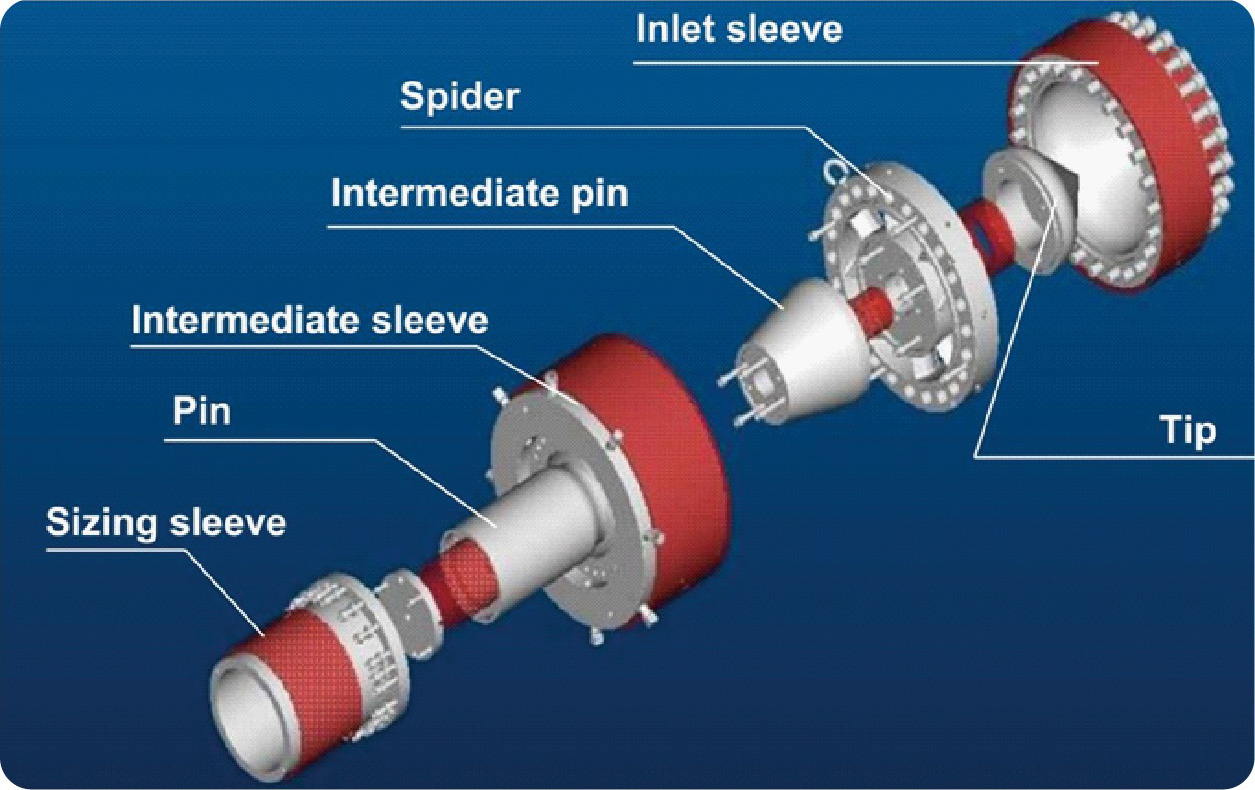

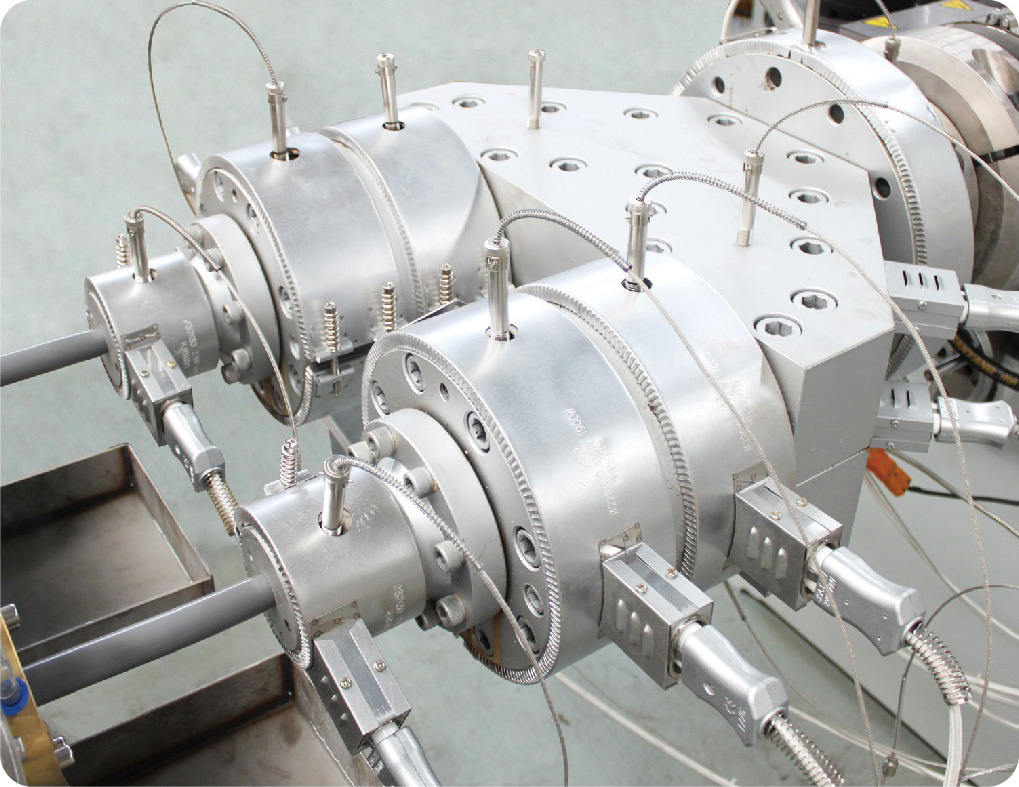

Die Head |

|

|

|

|

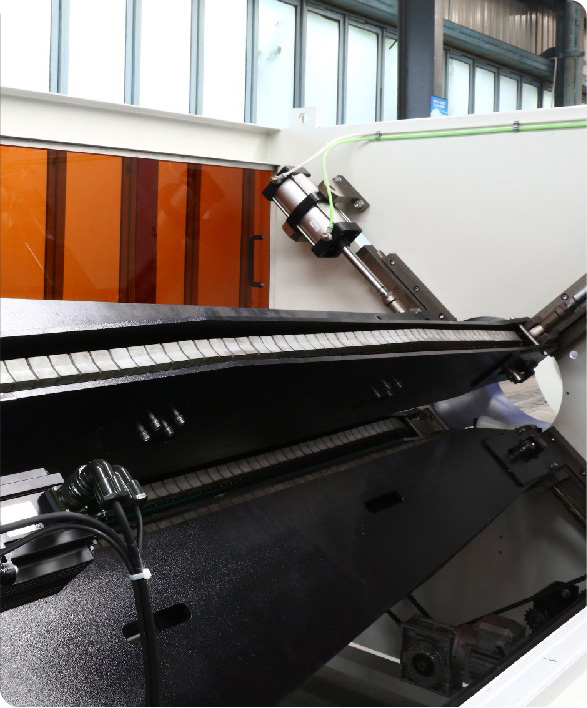

Vacuum Cooling Tank | Haul-off | ||||

|

| ||||

|

|

|

|

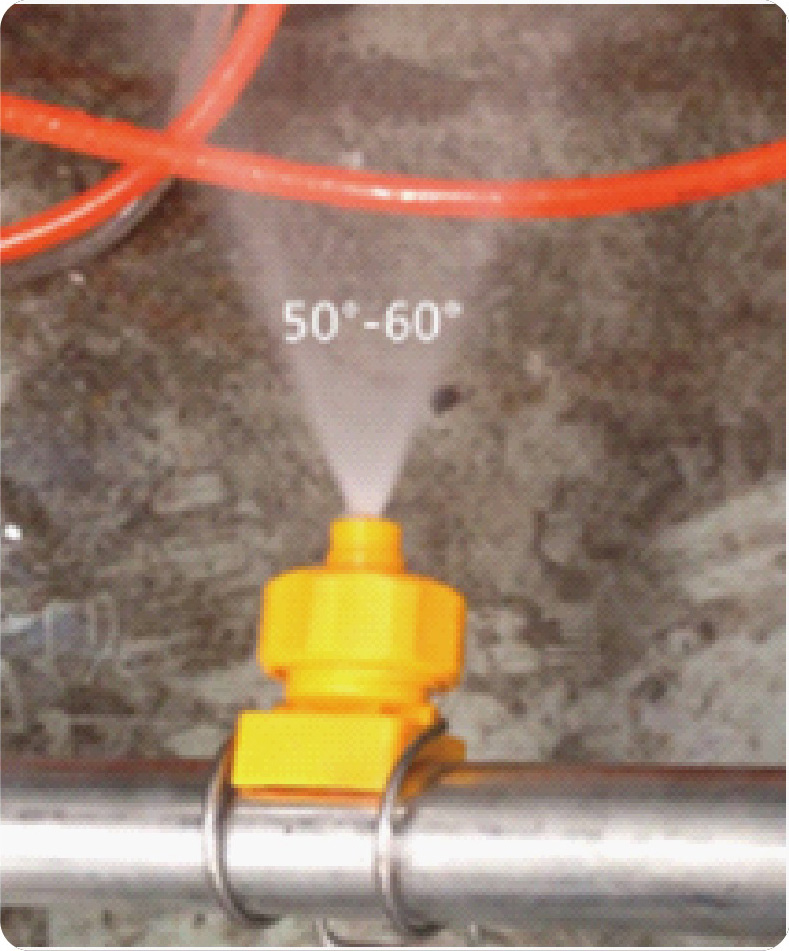

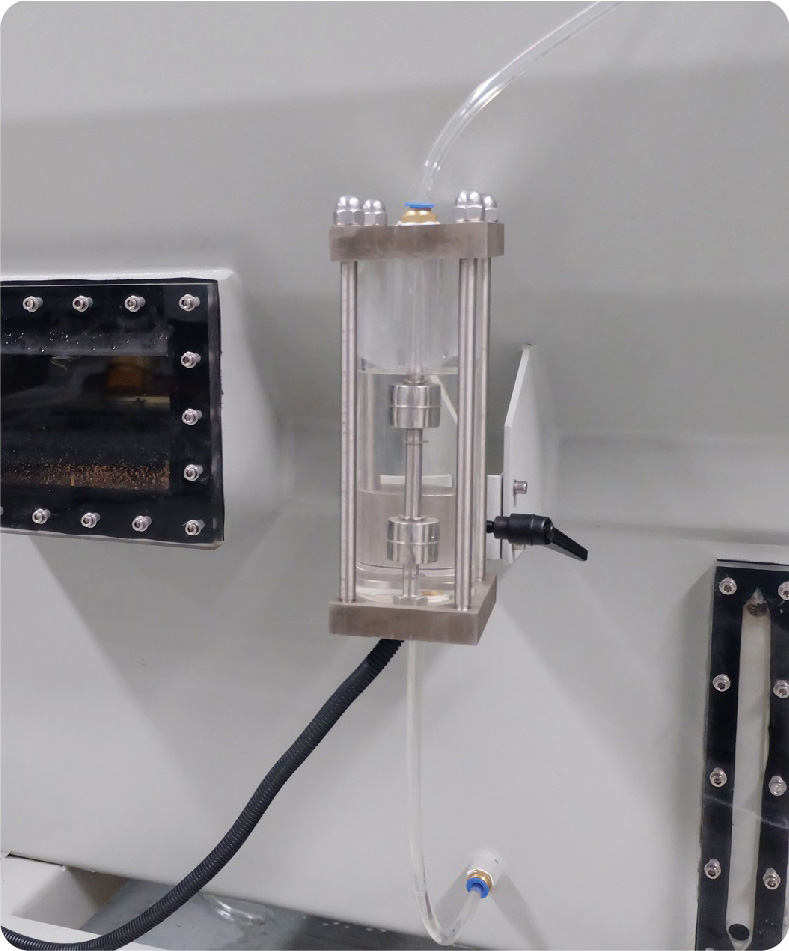

| Spraying Nozzles | Level Control |

Planetary Cutter |

|

|

|

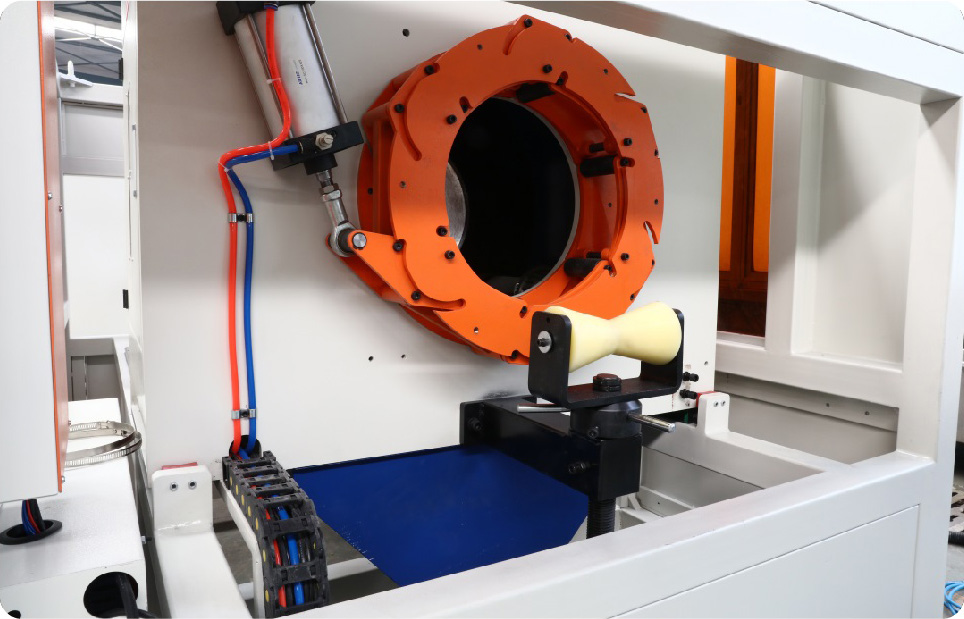

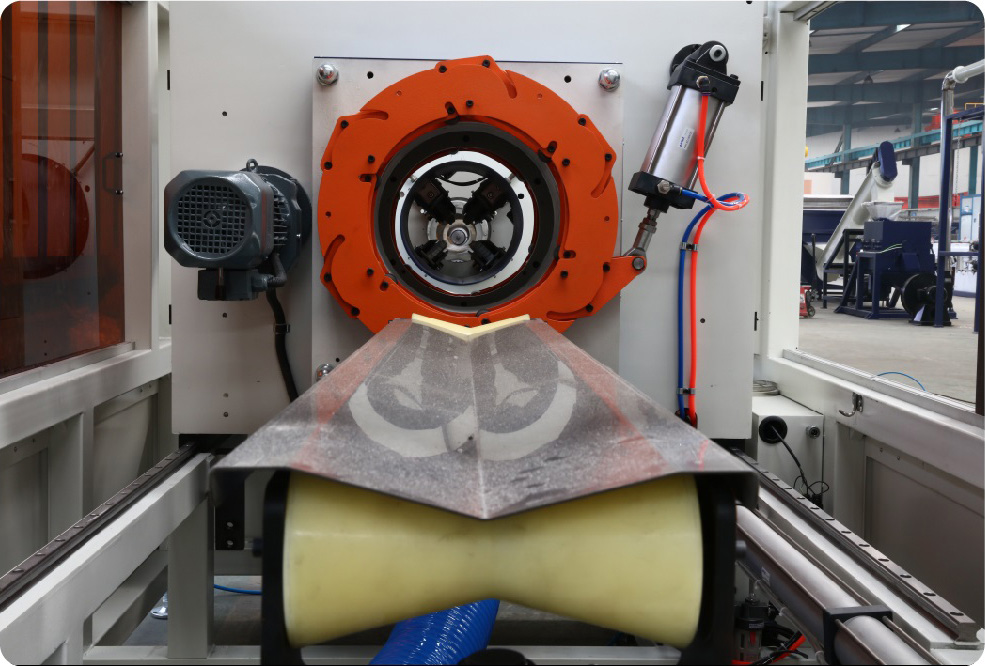

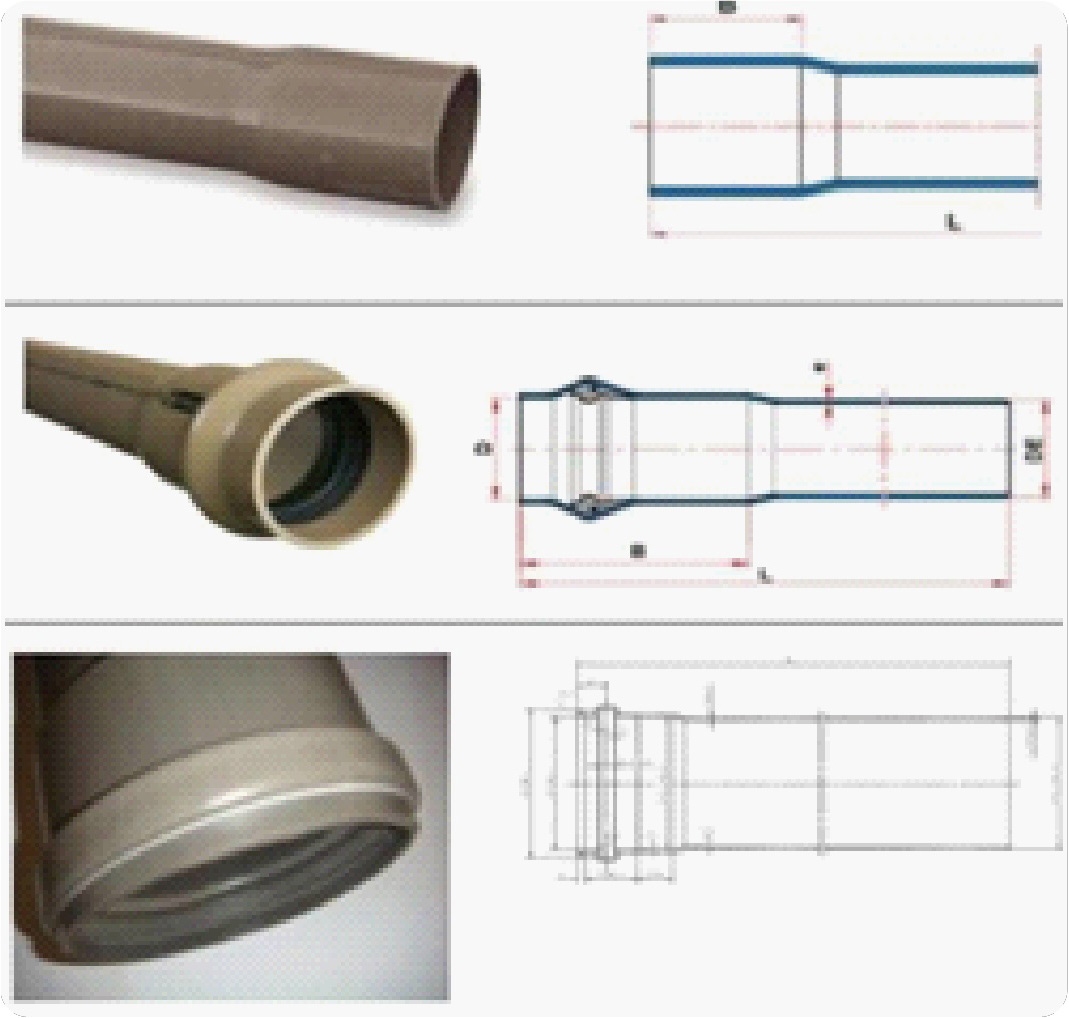

Belling Machine |

| U Socket |

|

| R Socket | ||

| Z Socket |

Technical Data:

| Model | O.D.(mm) | Extruder | Max.output(kg/h) | Max. Haul-off speed(m/min) | Motor Power(kW) |

| PVC32 Four | Φ16-32 | SJZ65/132 | 250 | 8*4 | 37AC |

| PVC40 Dual | Φ16-40 | SJ51/105 | 120 | 8*2 | 18.5AC |

| PVC63 Dual | Φ20-63 | SJZ65/132 | 250 | 12*2 | 37AC |

| PVC63 Single | Φ20-63 | SJZ55/110 | 180 | 12 | 22AC |

| PVC110 Single | Φ40-110 | SJZ65/132 | 250 | 6 | 37AC |

| PVC110 Dual | Φ40-110 | SJZ80/156 | 400 | 6*2 | 55AC |

| PVC160 | Φ50-160 | SJX65/132 | 250 | 5 | 37AC |

| PVC200 | Φ63-200 | SJZ80/156 | 350 | 6 | 55AC |

| PVC250 | Φ75-250 | SJZ80/156 | 400 | 5.5 | 55AC |

| PVC315 | Φ110-315 | SJZ80/156 | 400 | 5 | 75AC |

| PVC400 | Φ160-450 | SJZ92/188 | 600 | 3.5 | 110AC |

| PVC630 | Φ315-630 | SJZ92/188 | 800 | 2 | 110AC |

| PVC800 | Φ500-800 | SJP130/28 | 1100 | 1.3 | 160AC |

Support Hotline:

137 7322 2278